SWAYING STRAWS

//conducted_by_ flex.professional.research.group

//date_ october 2019

//location_ university of applied sciences, leipzig

//tools_ grasshopper, 3d-printing

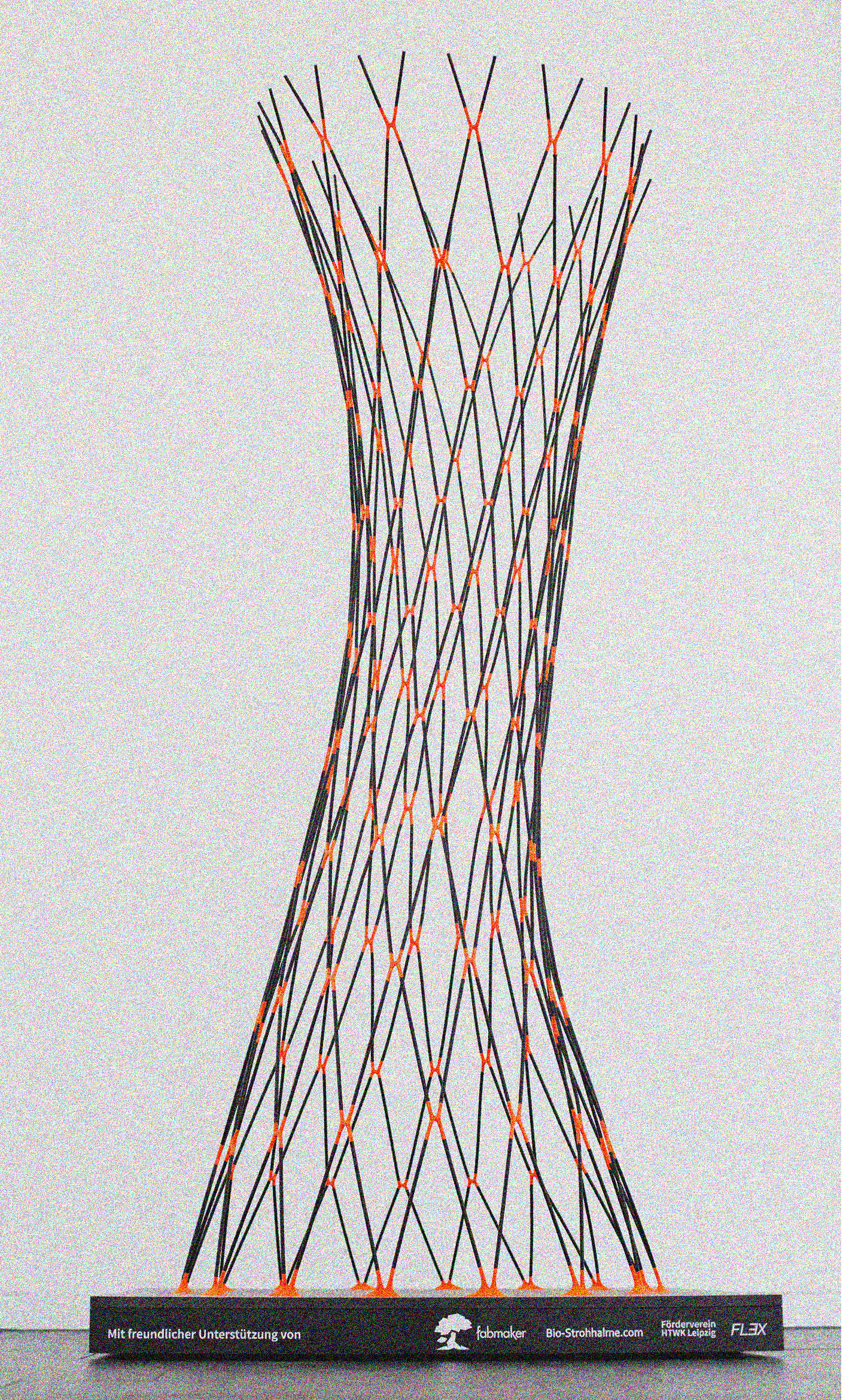

Swaying_Straws is a concept study on single-layer facade and roof structures. The structure combines serially manufactured standard components with unique additively-manufactured connectors. Despite the curvature of the overall structure, all rods can retain the same length. The amorphous shape of the framework is carried out solely by compact, geometrically individual node connectors.

//final model

![]()

![]()

The 3d-printed nodes form the core of the project. Their geometry is generated through a parametric design process. Based on an underlying mesh, the shape of each individual node is automatically created. The script also accounts for the variable lengths of the node-ends, ensuring that all connecting rods maintain uniform length. This approach highlights a potential advancement in automation for facade construction.

The 3d-printed nodes form the core of the project. Their geometry is generated through a parametric design process. Based on an underlying mesh, the shape of each individual node is automatically created. The script also accounts for the variable lengths of the node-ends, ensuring that all connecting rods maintain uniform length. This approach highlights a potential advancement in automation for facade construction.

//component layout

160 x individual node element

320 x uniform rod element

160 x individual node element

320 x uniform rod element

//me, assembling the model

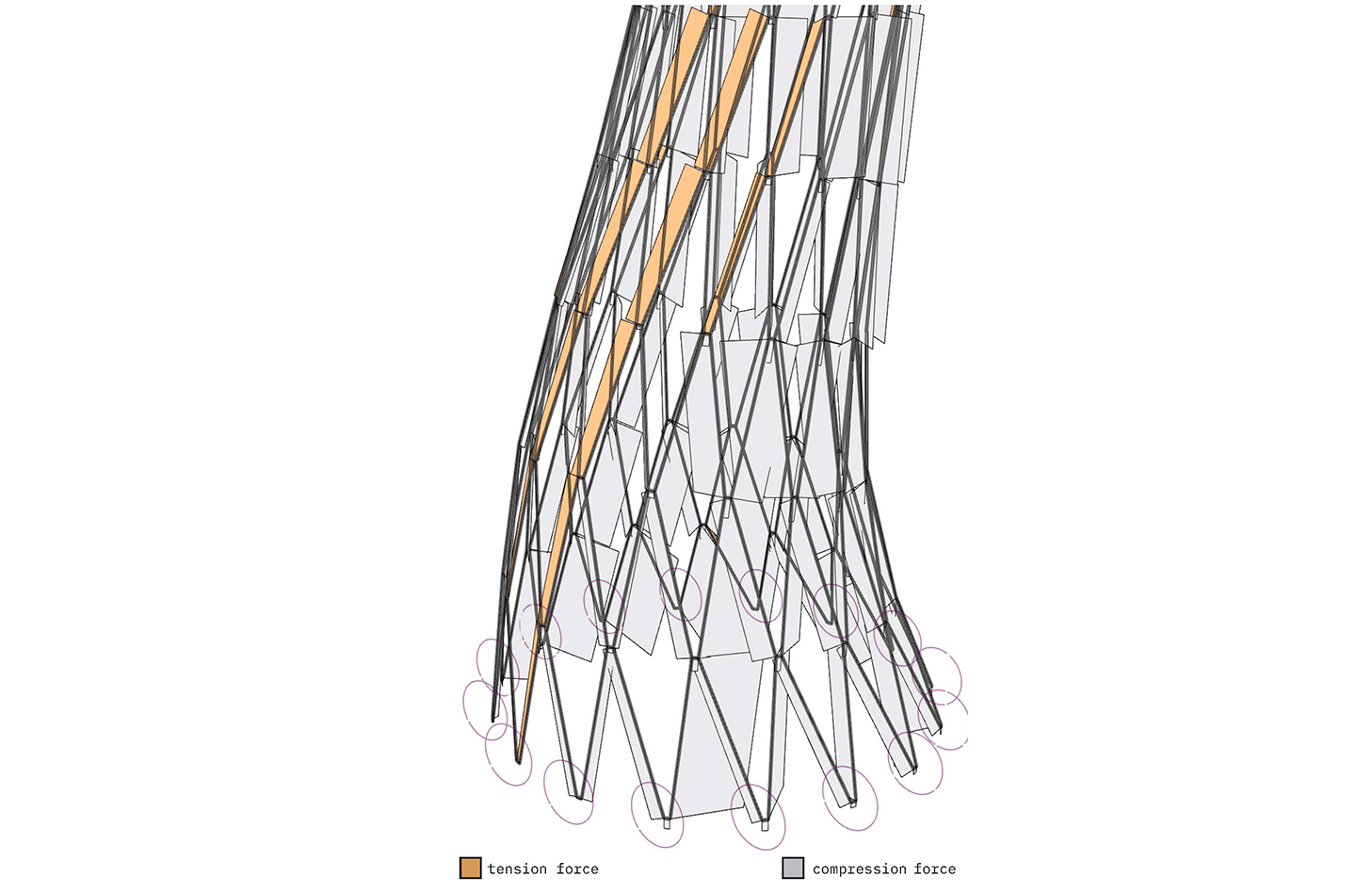

//structural analysis