ADDITIVE MANUFACTURING IN BUILDING CONSTRUCTION

//conducted at_ flex.professional.research.group

//date_ february 2020

//location_ university of applied sciences, leipzig

//methods_ SLS additive manufacturing, laser cutting

AMiCo focuses on developing an innovative, fully automated digital process chain from design to the fabrication of geometrically unique steel node connectors for single-layer framework applications in facade and roof constructions. The goal is to develop a parameter-based software pipeline capable of generating node connectors while taking into account constructive, static and fabrication-related boundary conditions.

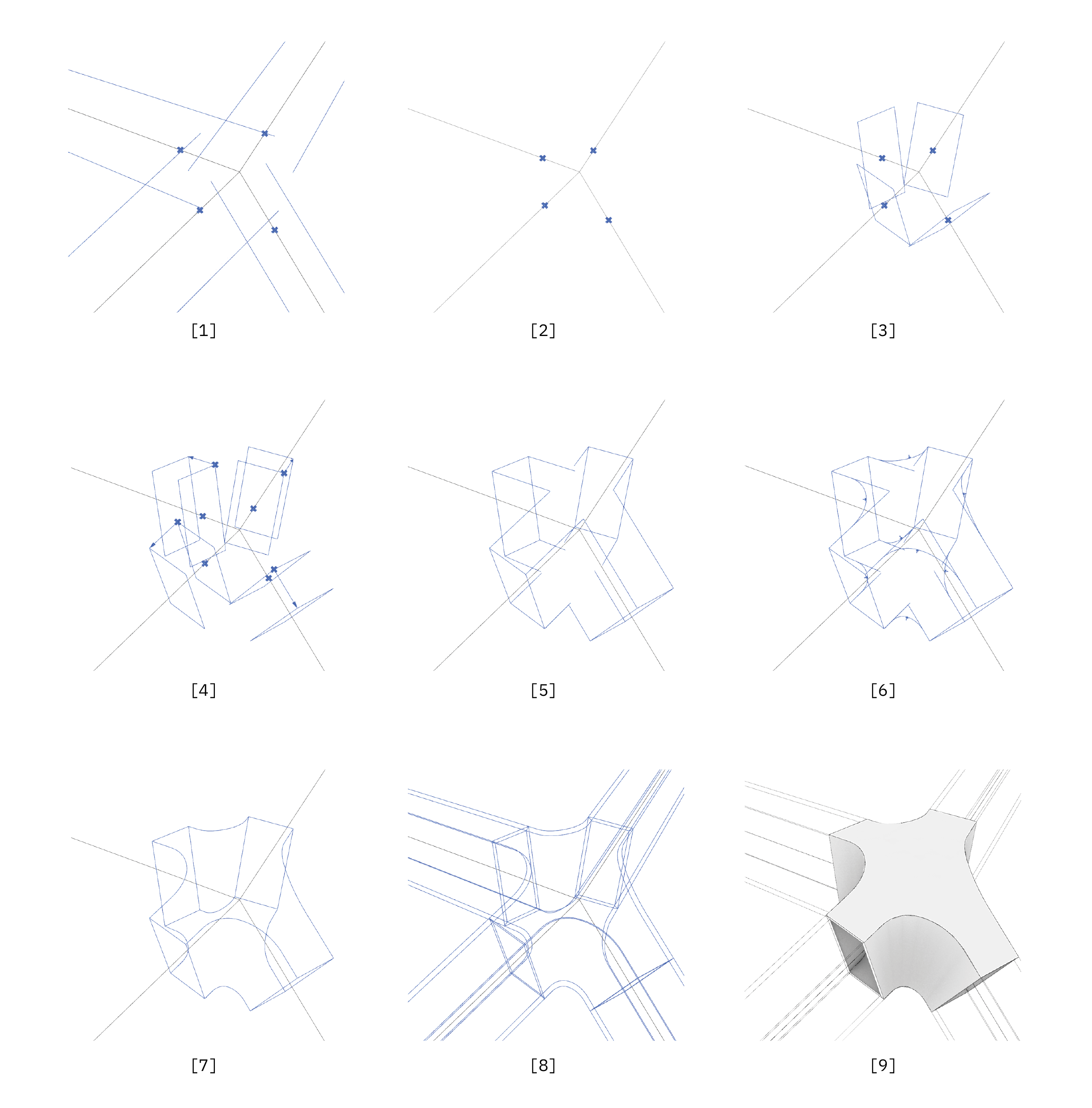

The core of the project is the algorithm-based design process of the node connector elements, which must meet all structural, technical and aesthetic requirements. Based on an input Nurbs surface, the script generates the necessary design and fabrication data within seconds.

[1]profile intersection [2]reference intersection [3]orient profile [4]offset profile [5]extrude profile tangents [6]bulge corners [7]join curves [8]offset curves [9]close profile

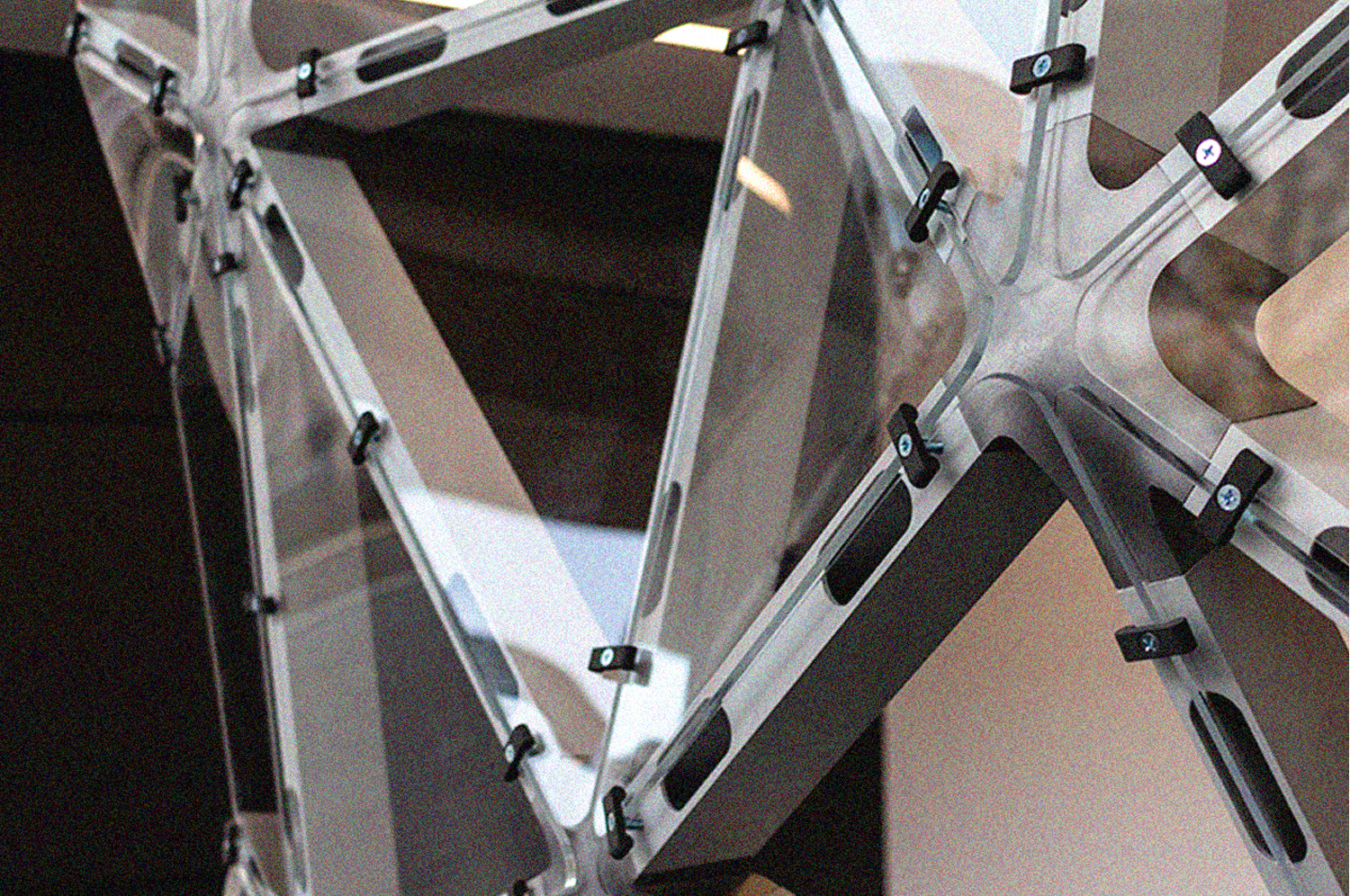

//node connector element

//node connector element profile parameter

[X] - x unit dimension

[Y] - y unit dimension

[XXX°] - angle between adjacent profiles

©HSMW

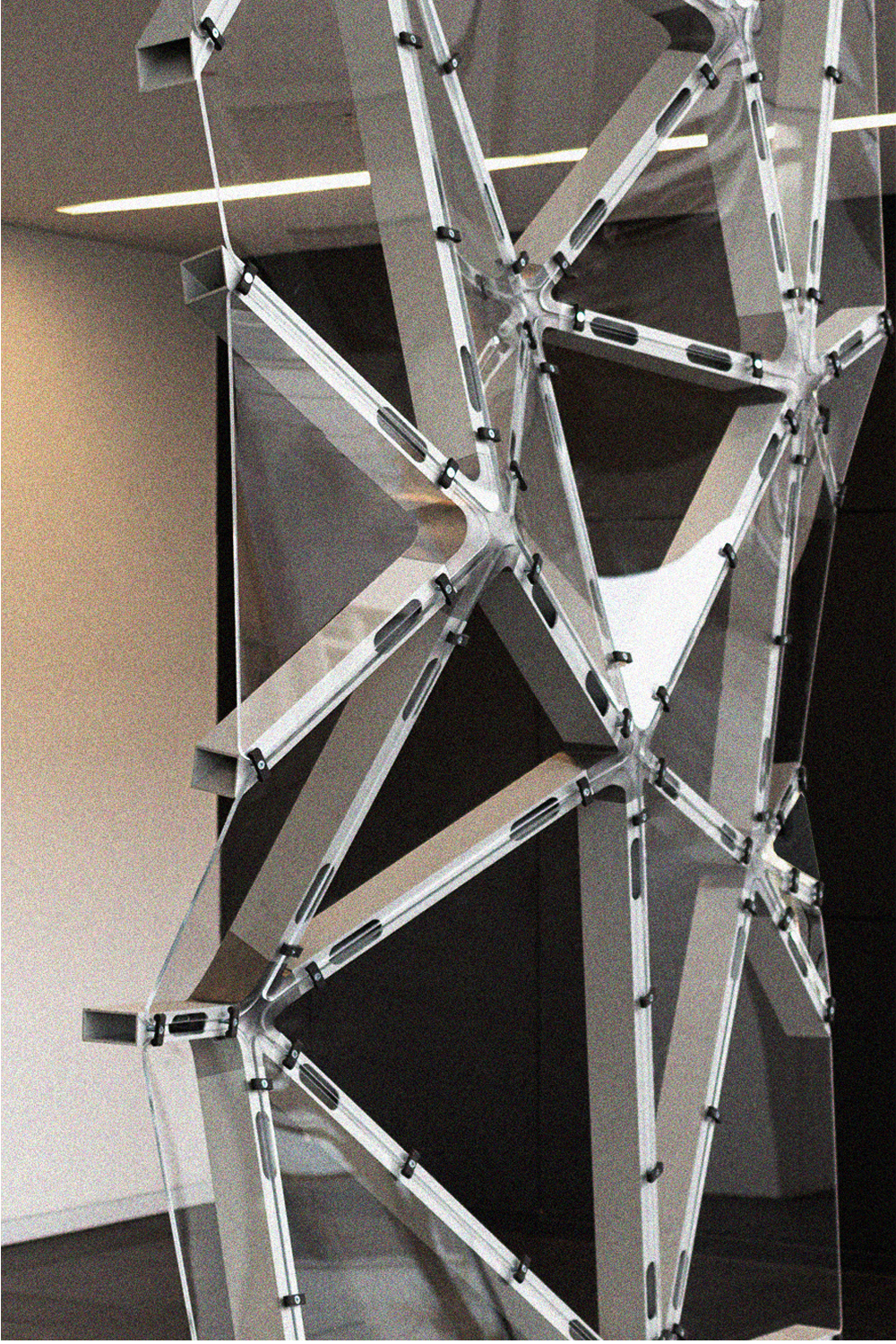

//final facade demonstrator

//final facade demonstrator