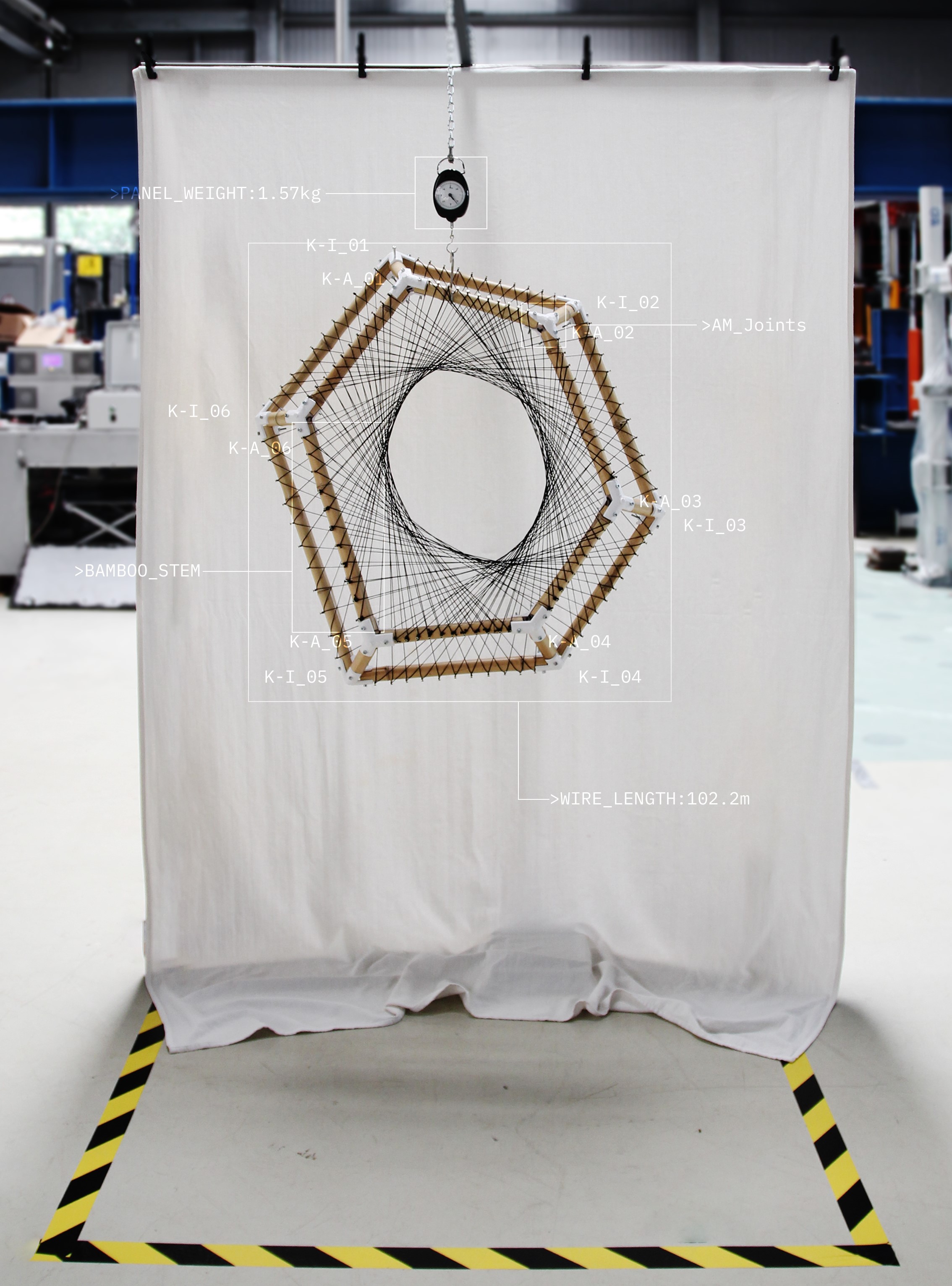

1.1_BAMBOO_PANEL

//date_ june 2020

//location_ university of applied sciences, leipzig

//tools_ grasshopper, python, 3d-printing, hand-winding

>....Bamboo Panel investigates the potentials of Bamboo as a rapidly growing building material for the manufacturing of ultra-lightweight facade skins. Individually 3D-printed connectors account for the natural occurring inaccuracies of bamboo stems and allow for a materially-informed computational workflow for the prefabrication of modular facade components.

>...component[24]

statistics:

bamboo_length: 6.75 m

bamboo_weight: 1.25 kg

wire_length: 102.2 m

wire_weight: 0.07 kg

screws: 36

screw_weight: 0.13 kg

am_joints: 12

am_joints_weight: 0.18 kg

...

...

...

panel_total_weight: 1.57 kg

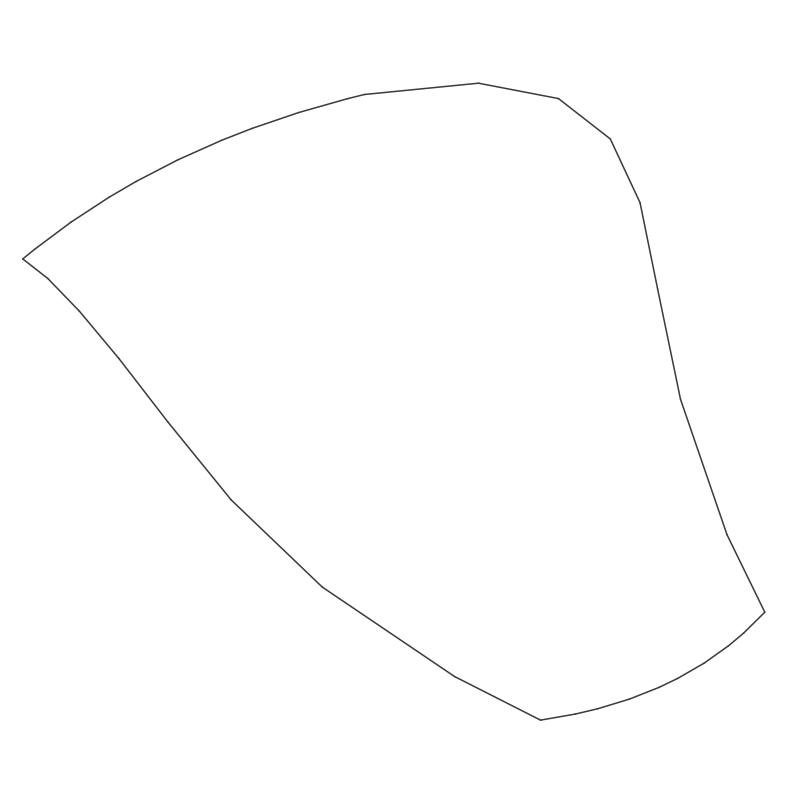

1. base_geometry

2.planarize_surface

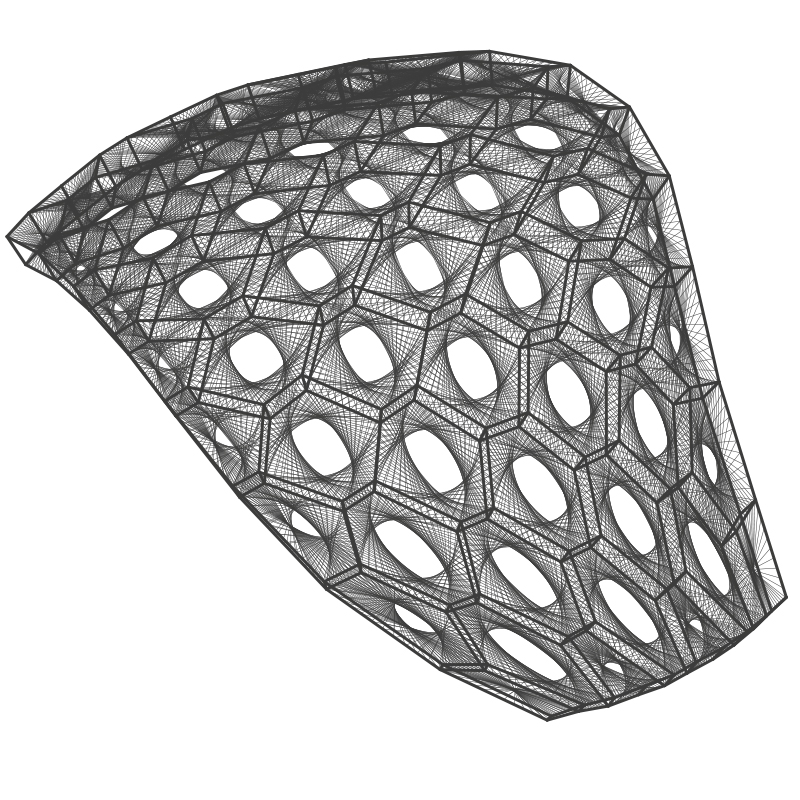

3. extract_wireframe

4. cover_frames

//With a tensile strength comparable to steel and the ability to bind large amounts of CO2, bamboo is still an underrrated material in the building industry. This project questions how the underestimated potential of bamboo can be improved in combination with digital manufacturing technologies to expand its application from a locally used material to an industrial building material for potential application in facade construction or temporary pavilion structures.